Singer 29K Industrial Patcher sewing machine

This model was designed as a cobblers shoemaking or patching machine.

The slim free arm with rack and pinion operated bobbin holder / hook are particularly suitable for sewing in confined spaces, but with an extension table, it will work well as a flat bed, walking foot machine.

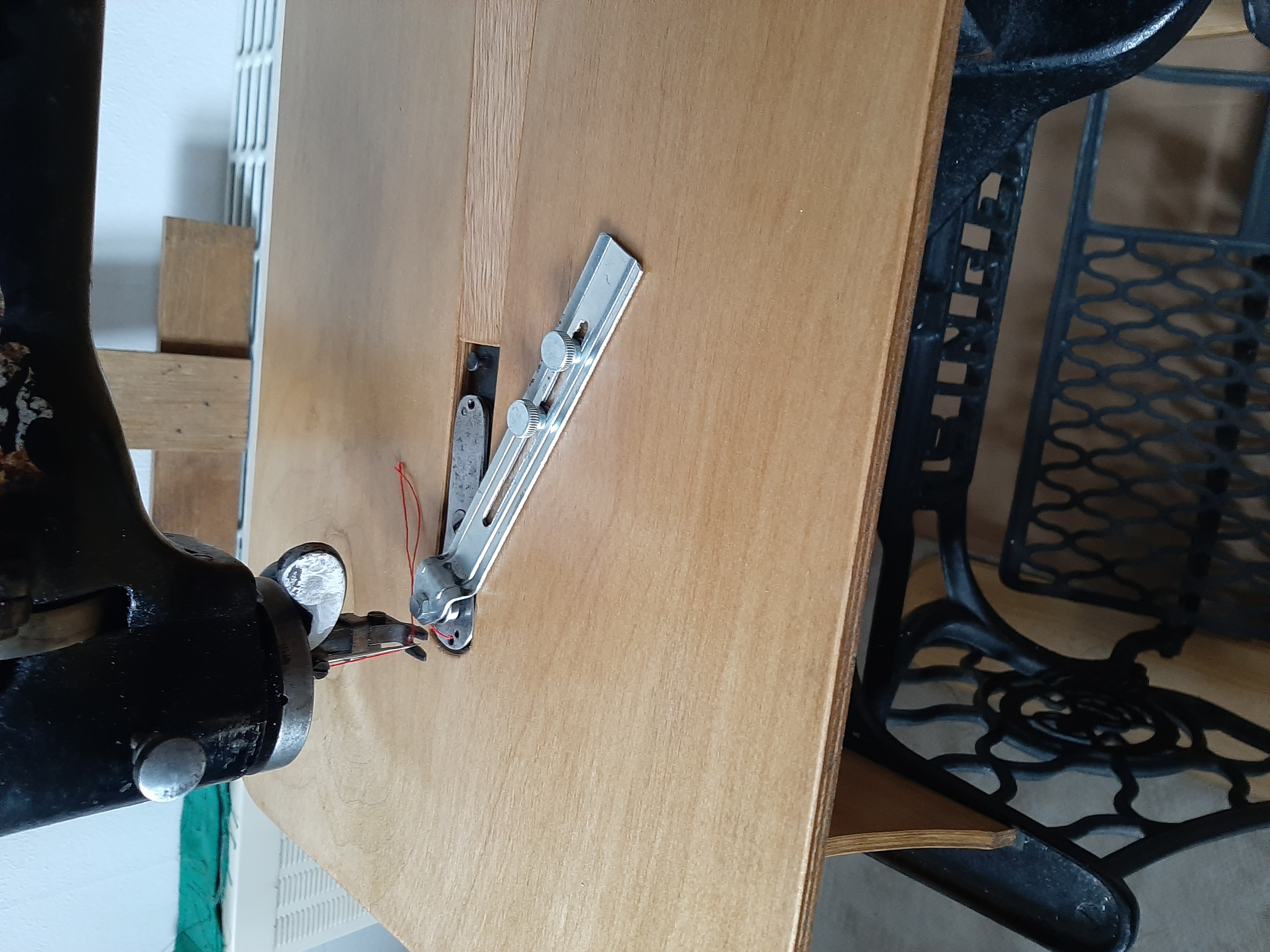

The machine came with a rough and ready table in open grained ply, but I made a more precisely fitting one from fine birch ply which I sealed and waxed.

I even made a fillet insert to sit on the free arm behind the throat plate, to prevent snagging on the workpiece.

Getting the correct concave shape underneath to sit on the curved top free arm took a while!

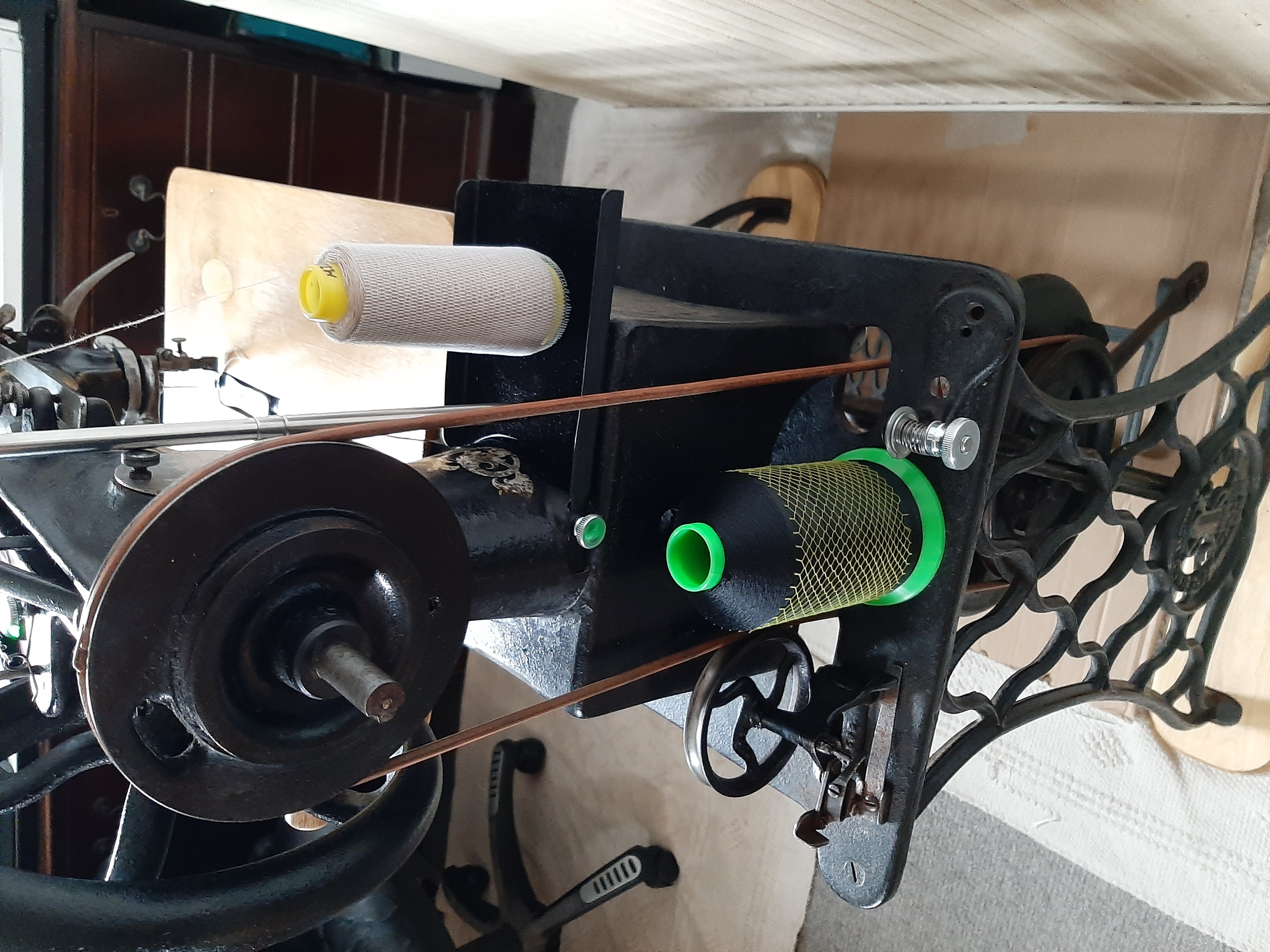

In addition I made a new handle for the front handwheel, made a spool support table with telescopic guide running to a new guide on the old spool mount and revamped the bobbin winder mechanism and guide.

The latter proved to be very necessary, because the small bobbins that it uses cannot be wound on standard Singer winders, or even on my standalone industrial winder, the bobbins centre diameter is too small.

A pair of pine skid feet / base feet to save the carpet finish it off.

A 'T Square' type fence was made for one of the few jobs where I needed quite a long straight seam run.

In the 'ToDo' list for a while, but now completed, an adjustable rotating wheel fence to sit close to the foot, to enable consistant edge to foot spacing in more fluid shapes.

This model is a 29K SV8 manufactured in 1917.

The SV designation stands for Special Variety, versions produced to order with specially hardened parts and or non standard extras, for particulary heavy duty industrial work or specialised jobs.

There is no information available that I can find as to exactly what this version of the machine was produced for, one can only speculate given the date, that it might have been used producing military equipment etc.

The needle holder shaft is reciprocated by a beam, which itself is moved via a cam slot in the front of the rear drive wheel. The drive wheel is either powered by a belt operated treadle or the front geared handwheel.

This arrangement is hugely strong and it will easily drive the needles through 8mm leather or 8 - 10 layers of heavy canvas.

The geared front handwheel is what I tend to use, as few of my jobs with it involve long seam runs, more often precisely positioned short runs, such as reinforced handle attachments etc.

A unique feature of the machine, is the ability to rotate the walking foot through 360 degrees.

Since there are no feed dogs and the feed is from the serations on the bottom of the foot, this allows a change in sewing direction without moving the workpiece.

Very usefull in confined areas.